INTRODUCTION

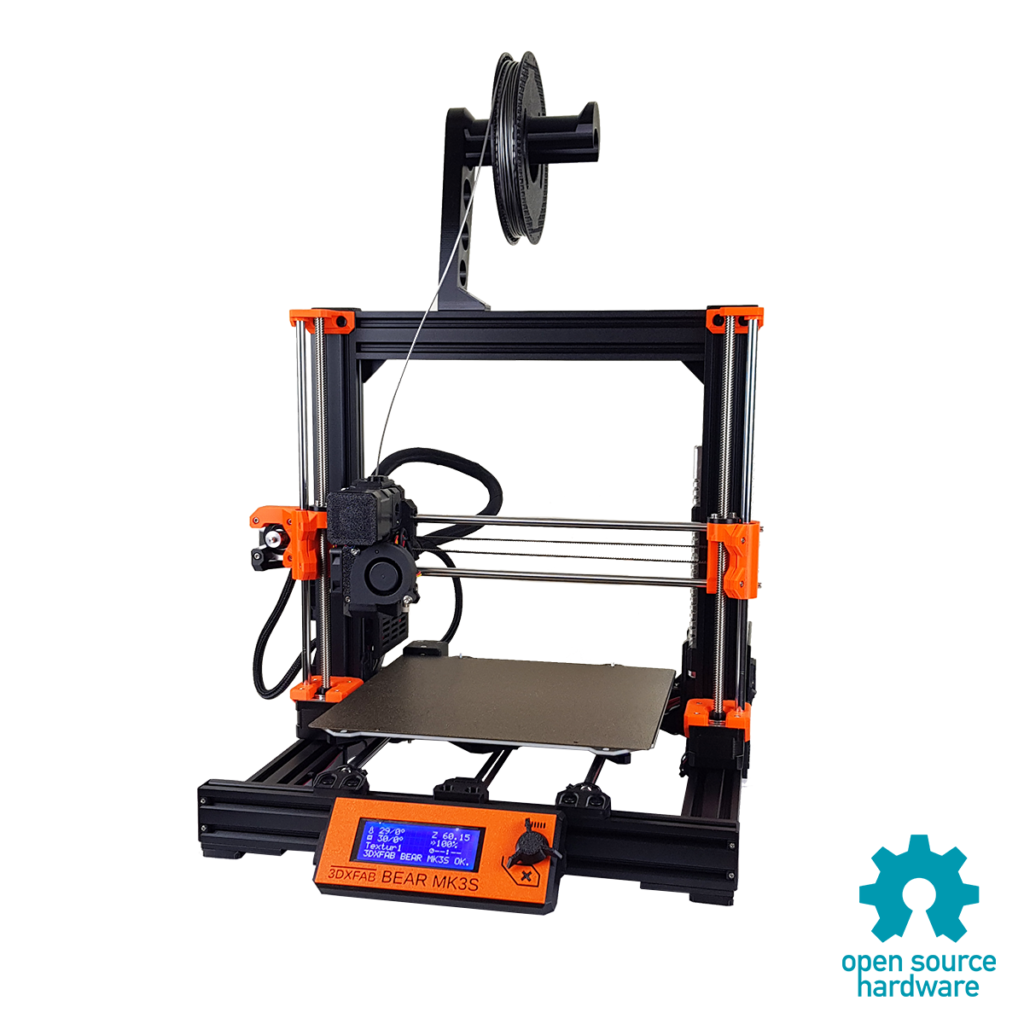

We’ve made it, our fully open-source BEAR MK3S 3D Printer is finally here in Malaysia! But what makes it so special compared to the Original Prusa i3 MK3S+ ? Are clones any better ? You have come to the right place! Below we will answer the most frequently asked questions and also to give you a little insight into our engineering & hardware that is on board the BEAR MK3S 3D Printer.

Let’s dive straight right into the first question. (Estimated reading time: 15 minutes)

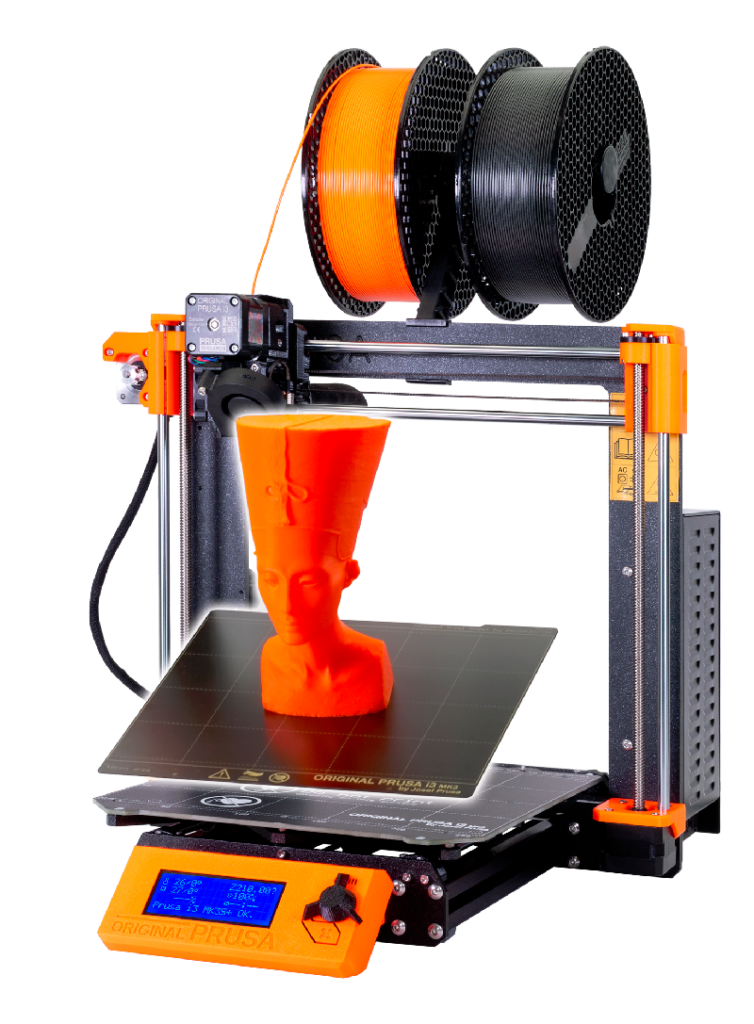

Is the BEAR MK3S a clone of the PRUSA MK3S+ ?

Short answer, No. The BEAR MK3S is not a direct clone of the Prusa i3 but an open source project done to further improve the Prusa MK3S hence BEAR MK3S. The BEAR Project was initially founded by Grégoire Saunier. The BEAR Project is an active community project on GitHub.

What is sold online, for example on AliExpress of the Prusa BEAR 3D Printer is simply a kit from this open-source project like the Voron 2.4/V0 kit. But bear in mind (pun-intended) the quality of those online kits can be somewhat questionable. 3DXFAB Research & Development had also brought a few BEAR kits online from various platforms to justify its quality and price.

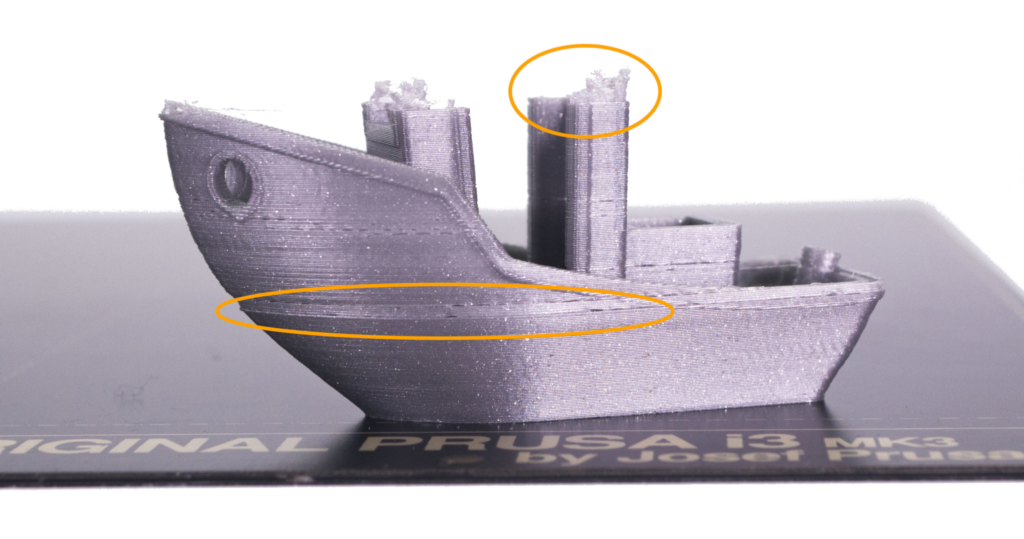

Here are a few of the problems that we have identified :

- Low quality HotEnd which was lined with PTFE

- Hard to square frame as those frames were assembled using through hole screws

- Missing parts, in our case the two pin Molex connector for the Einsy Rambo board

- Severely warped MK52 Heated Bed

- Bad machining on the Dual-Drive gears

- An inductive probe with the worst repeatability and temperature drift

- Low quality RepRap LCD with hit-or-miss encoder

- Low quality linear rods & linear bearings

- Incorrectly spec. stepper motors and part cooling fan

- Printed parts are not included with the kit

- Run the risk of assembling the kit incorrectly and damaging components

Why named it as BEAR MK3S but not BEAR MK3S+ ?

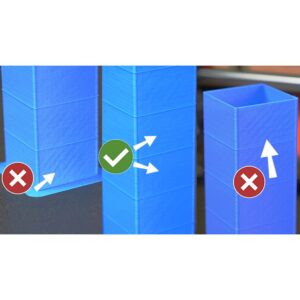

The sole purpose of the BEAR Project is to fix any flaws found on the Prusa i3 MK3 line of printers, to name a few would be the lack of tensioner on the X and Y Axis, incorrect filament path in the extruder body R3-R5, weak Y-carriage bearing holders, etc.

When Prusa Research launched the new MK3S+, most of the upgrades & fixes were referenced from the BEAR Project. These flaws and upgrades to the Prusa i3 MK3S+ were all fixed in the BEAR MK3S.

With that in mind, how do we solve those issue u asked ? Well, engineering and a little tad of magical hardware of course !

HARDWARE

HotEnd

Most Prusa BEAR kits purchased from the web often comes with a PTFE lined HeatBreak, which is not only bad for High-Temp printing but a pain to replace which requires the teardown of the entire HotEnd assembly.

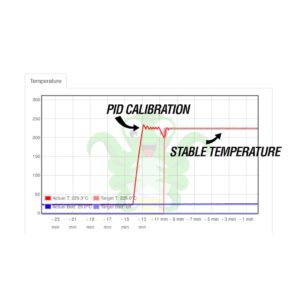

Not only that, the HeatBlock is also made from a mysterious aluminium alloy through casting which can dramatically reduces it strength and structure integrity at higher printing temperatures > 240°C . It can also cause severe temperature fluctuation due to its lower density, even when PID-Tuned !

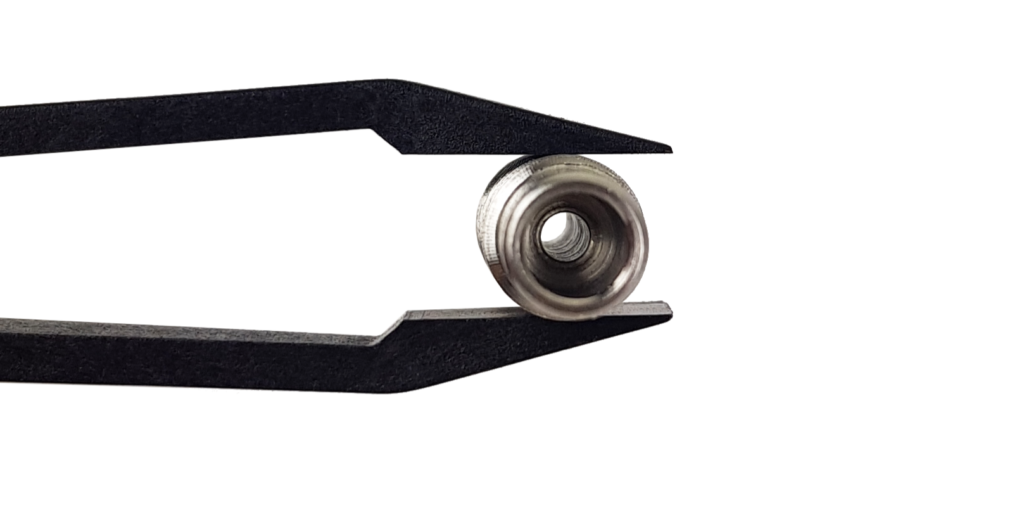

We couldn’t just install any all-metal HeatBreak to the BEAR MK3S to enable high-temp printing. This is because thermoplastics loves to stick to metal which is what a HeatBreak is made out of. A HeatBreak with an internal surface roughness of Ra > 0.7 will certainly clog when printing PLA (commonly found in those cheap all-metal V6 HeatBreaks on the market).

This is where our HeatBreak comes in. 3DXFAB Titanium V6 HeatBreak feature a refined internal surface finish (Ra < 0.3) to reduce extrusion force and improve retraction reliability. Made from Grade 5 Titanium, these HeatBreaks are exceptionally strong and have lower thermal conductivity than stainless steel HeatBreaks, allowing it to keep the cold side of the HotEnd even colder.

Did you know that the Original Prusa i3 MK3/S/+ still uses a stainless steel HeatBreak ? Fear not, 3DXFAB Titanium V6 HeatBreaks are the perfect upgrade for printing at higher temperatures, helping to maintain a sharply defined melt zone at higher temperatures with without clogs.

Fun fact : Our Titanium V6 HeatBreaks can print PLA with an ambient temperature of up to 34°C without the worry of clogs! Perfect for a hot and humid country like Malaysia.

Dual-Drive Gears

(1) Missing teeth definition; (2) Incorrect distance from head to teeth profile; (3) Incorrect tooth geometry; (4) Not optimal tooth width; (5) Incorrect overall length, not hardened

[Based on Bondtech 1.75mm Drive Gears]

Bad teeth definition can lead to slipping of the filament which can introduce retraction inaccuracy during printing and create plastic deposit on the gear. Cheap dual-drive gears usually comes without any heat treatment or a nickel coating, hence there are not suitable for abrasive polymers.

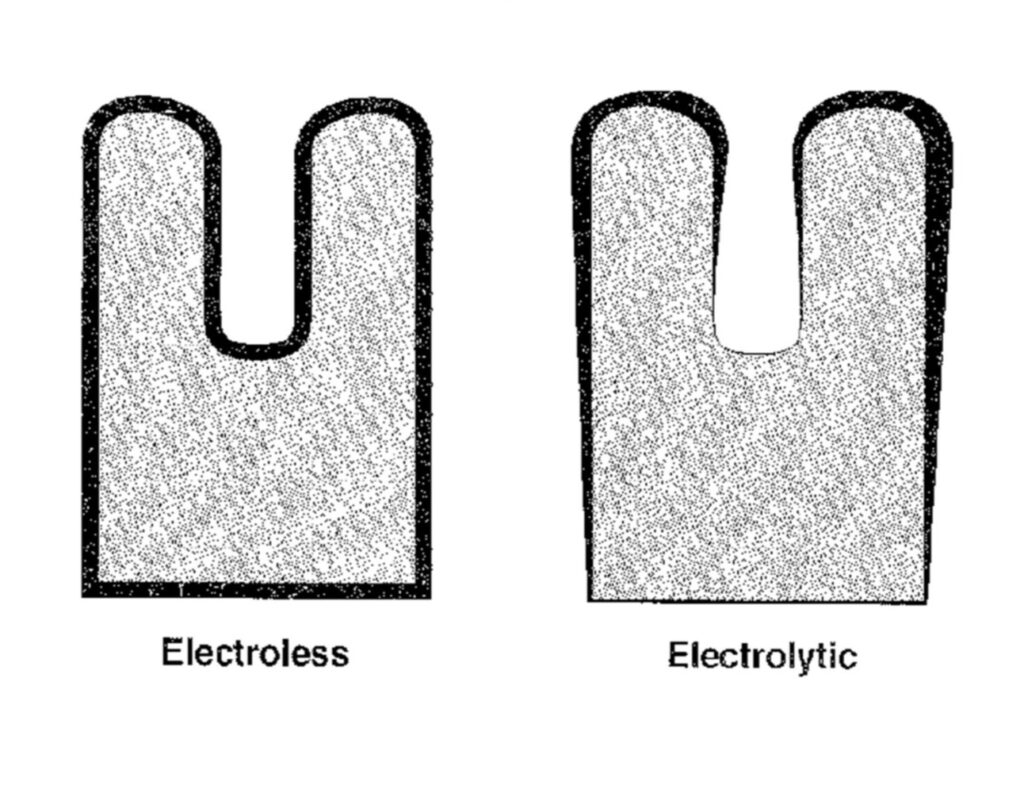

3DXFAB Dual-Drive Gears follows the exact drawings from BondTech down to the micron. Our gears goes through heat treatment first, done to harden the steel then to final electroless hard nickel coating, done to provide extra protection against corrosion, erosion, and abrasion. Now u can print abrasive polymers like XT-CF20 worry free !

Fun fact : Our gears are slightly in a yellowish color due to the hardening and plating process.